Hale Hana kila

ʻAʻole hiki ke hoʻokaʻawale ʻia ke ola o kēia mau lā mai ka hale kila, inā he hale kaʻa kaʻa kiʻekiʻe, nā mokulele, nā kahua pāʻani a i ʻole nā halepaku, aia nā hale kila.

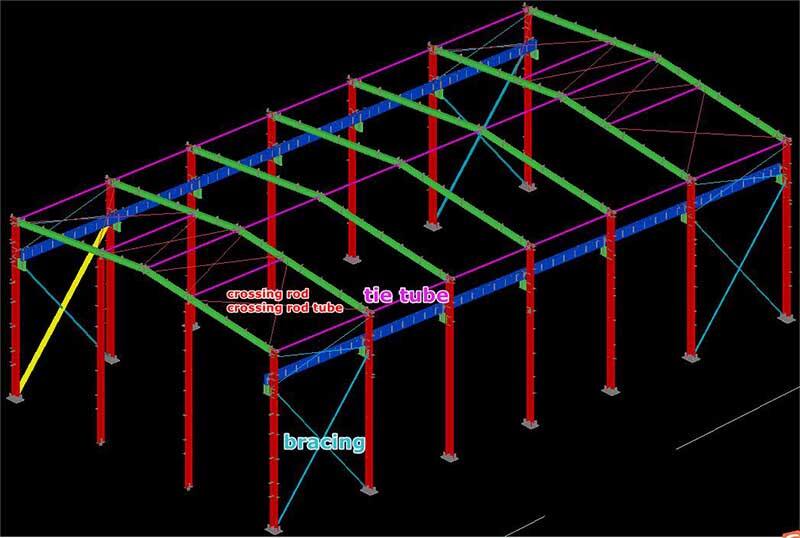

I kēia manawa, ʻo ke ʻano maʻamau a maʻamau o ka hale ka Gable frame.

He ʻōnaehana hana kuʻuna ʻo Gable frame, ʻo ke kiʻi nui o luna o kēia ʻano hale e pili ana i ka lāʻau inclined kaola, kolamu ʻaʻa paʻa, kākoʻo, purlin, kaula kaula, gable frame a pēlā aku.

ʻO ka Gable frame light house steel structure nā hiʻohiʻona o ka ikaika maʻalahi, ke ala hoʻoili ikaika māmā, ka hana wikiwiki, ka hana maʻalahi o ka hale hana, ka wā kūkulu pōkole, a me nā mea ʻē aʻe, no laila ua hoʻohana nui ʻia i nā hale ʻoihana a me nā hale kīwila e like me ka ʻoihana, kālepa, moʻomeheu a me ka ʻoliʻoli lehulehu.

Hoʻolauna hoʻohui huahana

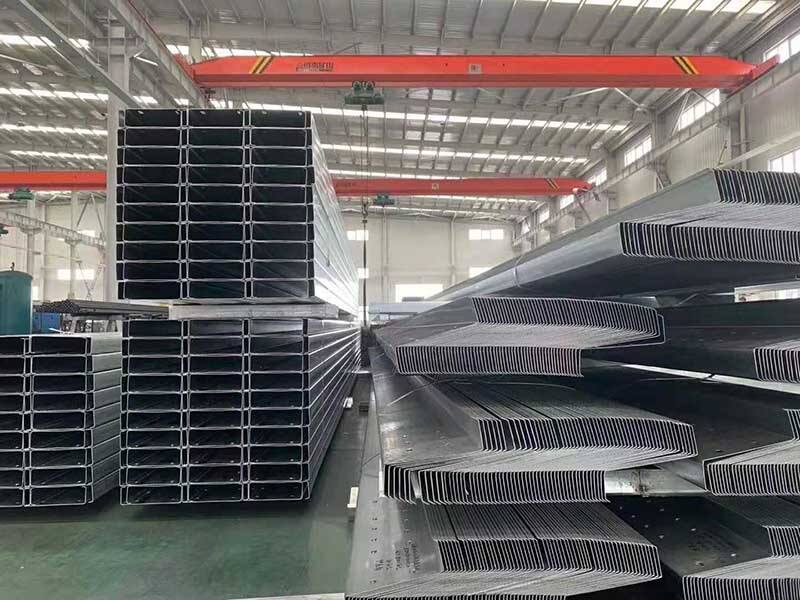

kolamu kila

ʻO lākou nā lālā lawe ukana nui ke kuleana no ka hoʻoili ʻana i ka ukana o ka superstructure i ke kumu. Pono ka hoʻolālā o nā kolamu kila e noʻonoʻo i nā kūlana o ka honua, ka nui o ka ukana, a me ke kiʻekiʻe a me ka hoʻolālā o ka hale holoʻokoʻa e hōʻoia i ka ikaika a me ka paʻa.

Kaola kila

Hoʻohana pinepine ʻia nā kaola kila ma ke ʻano he nui-span beam, hiki ke pale a hoʻololi i ka ukana a me ka ikaika kulou o nā papa hana ʻē aʻe, i mālama ʻia ke kaulike ma waena o nā papahele, a hiki nō hoʻi ke kūʻē i ke ōlaʻi.

Purlin

Kākoʻo a hoʻopaʻa ʻia i nā panela hale. Hoʻololi ʻia nā ukana o ka hale, ka hau a me ka makani i ke kolamu kila a me ke kaola kila, no laila e puʻunaue like ʻia lākou i ke kumu e pale aku ai i ka ikaika nui a me ka pōʻino.

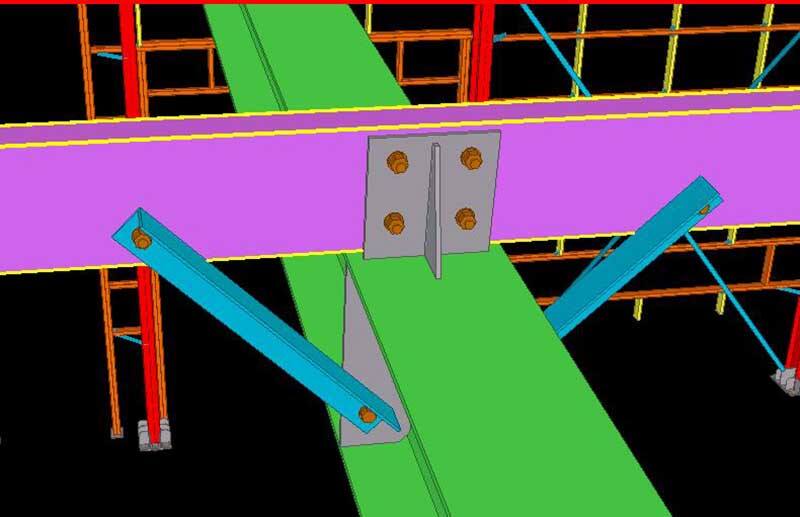

Paʻa heleuma

Hoʻopaʻa paʻa ʻia ka hale i ke kumu i hiki ai i ka hale ke pale i nā pilikia o nā ʻano ikaika like ʻole, me nā haʻahaʻa static, dynamic, a me ka makani.

Paipu pili

E hoʻololi i nā ikaika axial, e like me nā haʻalulu makani, ka hoʻokele ʻana i nā puʻupuʻu longitudinal, a me nā ikaika ōlaʻi, e hōʻoia i ka paʻa a me ka palekana.

Ke kākoʻo

E hōʻoia i ka paʻa o ke kūkulu ʻana, ka hoʻoili ukana, ka hoʻonui ʻana i ka hana seismic, ka hoʻonohonoho ʻana o ka lewa, a me ka hoʻemi ʻana i nā kumukūʻai mālama.

Paʻa nā kuli (Puliuli)

Hoʻohana ʻia ia e hoʻopili i ka lāʻau kila a me ka purlin kākoʻo i ka lāʻau haʻahaʻa haʻahaʻa e hōʻoia i ka paʻa o ka mokulele beam.

Eave Angle

E pale i ka hale a hoʻonui i ka palekana o ka hale.

Laau Kea

Hoʻonui i ka paʻa, hoʻonui i ka hiki ke amo, ka pilina a me ka hoʻopaʻa ʻana i nā mea kila like ʻole, a me ke kūʻē ʻana i ka makani a me ke ōlaʻi.

Paipu koʻokoʻo

E mālama i ka paʻa o ka lālā nui, e hoʻonui i ka ʻoʻoleʻa a me ka paʻa o ka hale ma ka hāʻawi ʻana i ka fulcrum lateral, a pale i ka deformation lateral nui a me ka paʻa ʻole o ka hale.

ami

Hoʻopuehu i ke koʻikoʻi, pale i nā noho uwea a hoʻonui i ka paʻa hui.

hāʻawe

'īpale

PU sanwiti panel

B1 ʻAi ahi, pale ahi

Huluhulu pōhaku

He pale ahi, pale ahi

ʻO ka papa sandwich EPS

B2 ʻAi ahi, puhi maʻalahi

Huluhulu aniani

Puhi maʻalahi, + Graphite, pale ahi

hoʻokahi papa

Ka hihia o ka poʻe kōkua

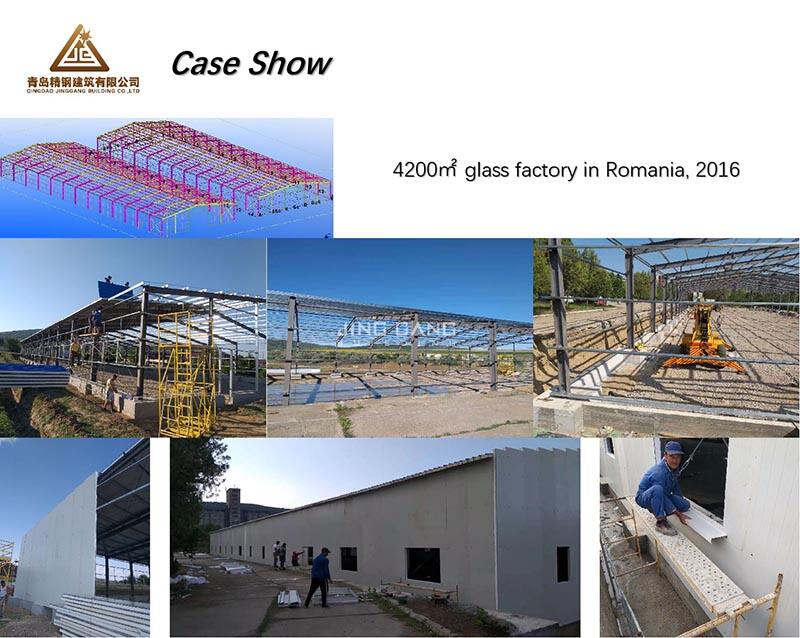

He ʻoihana ʻoihana ʻo Jinggang e hana ana i nā hale kila like ʻole e like me ka hale hana kila, ka hale kūʻai kila, ka hale kila galvanized, a me nā mea ʻē aʻe. Ua lawe ʻia kā mākou huahana i ʻAmelika, Russia, Saudi Arabia, Philippines, Iapana, ʻApelika Hema a pēlā aku.

Hoʻolālā, helu, a hoʻolālā ʻo Jinggang i nā hoʻonā piha a me nā hoʻolālā o ka hale kila e like me nā kūlana Kina a me ka honua, e hui pū ana i ka ʻenehana hou.

ʻO Jinggang ke kumu nui a me ka hoʻonohonoho ʻana o ka hoʻolālā

1.Unified maʻamau no ka hoʻolālā hilinaʻi o ka hale (GBJ50068-2001)

2.Standard no nā huaʻōlelo a me nā hōʻailona i hoʻohana ʻia i ka hoʻolālā ʻana i nā hale kūkulu hale (GB/T50083-97)

3. Kūlana no ke kaha kiʻi (GB/T50105-2001)

4. Load code no ka hoʻolālā ʻana i nā hale kūkulu hale (GB50009-2001)

5. Code no ka hoʻolālā seismic o nā hale (GB50011-2010)

6. Code no ka hoʻolālā ʻana i nā hale kila (GBJ50017-2003)

7. ʻO nā kikoʻī loea no nā hale kila o ka māmā-kaumaha me ke kiʻi ʻoniʻoni (CECS102:2002)

8. ʻO ke code ʻenehana o nā hale kila lahilahi i hana ʻia i ke anu (GB50018-2002)

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

ʻAʻOLE

ʻAʻOLE

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

SQ

SQ

ET

ET

GL

GL

HU

HU

MS

MS

KA

KA

BN

BN

BS

BS

LA

LA

MI

MI

KK

KK

UZ

UZ

HAW

HAW